|

Use of metal braces to connect logs in cut cups. German alternative to dovetail

and brace connection

When we plan and design a wooden house, we want to see it large and spacious, wanting to get away

from cramped city apartments. Today it is not uncommon for a house with dimensions exceeding 8, 10

and even 12 meters on each of the walls. Everything could be good, but to find a flat 12-meter (more

precisely 13-meter, taking into account the length of angles) pine is a great luck. But to find it half a lot,

it still needs to be brought, for example, from Vologda forests to St. Petersburg. But here the problems

of principle or financial nature begin, which makes the use of long meters (i.e. logs longer than 6 meters)

usually economically unjustified.

|

So what to do? Our grandfathers somehow came out of this situation. Correct, using the dovetail end

joint of the logs (see figure on the right). As a rule, all end joints of logs are made in cuts, and since the

place of joint is closed by the upper rim, on the side there is an impression of using an entire log for the

whole wall.

Unfortunately, the dovetail node has a significant disadvantage - over time such a compound dries and

needs to be periodically clipped, which no one usually ever does.

|

|

Connection

"dovetail" - it is NOT production of our company

Connection

"dovetail" - it is NOT production of our company

|

As a result, the density of the corners of the cut is deteriorated, gaps appear, the house loses integrity

and the walls can start to swim.

|

The more modern solution used by the vast majority of construction companies has been the use of

metal construction brackets (figure on the right).

As you understand it is also not the perfect way out. At the points of attachment of the clamps there is a

very strong pressure on the wood (the area of the clamp tooth is small and the weight of the upper

crowns is significant).

|

|

Application

of building cramples is NOT production of our company

Application

of building cramples is NOT production of our company

|

As a result, the bracket pushes the tree at the points of contact, gaps arise, which then affect the density

of the logs in the cuts, and then the problems already familiar to us, described above, arise.

In addition, the contact of steel clamps with the tree creates rust, further leads to the occurrence of

affected areas of wood.

So what to do? As is known, the genius of mankind has always found solutions from seemingly hopeless

situations. This problem has also been solved. As we have already said, the specialists of Rus Brevenaya

company have many years of experience not only for clients from Russia and CIS countries, but also for

customers from Scandinavian countries (especially Norway), Germany and other countries of Western

Europe.

At the same time, we always try to adopt all the best that is in the world experience of building wooden

houses. This was the case with "the hanging of external corners" (in more detail here - this technique is

rarely used by anyone in Russia, although it is very effective) and with the use of galvanized metal ties

for connecting logs.

These two approaches are the real know-how of Rus Brevenskaya, and together with the other

technological approaches discussed in this section, create a unique competitive situation supported by

an additional reasonable price policy of the company.

But back to our topic - docking logs in a way we borrowed from German colleagues.

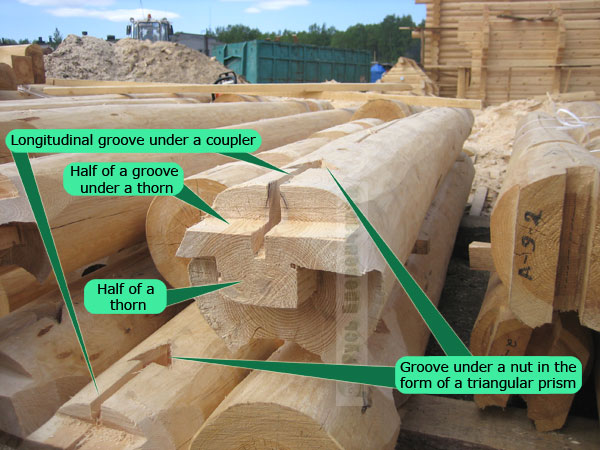

Figure 1 shows schematically (plan view and side view) the use of a tie bar representing a galvanized

stud about half a meter long with a thread at both ends. The pin is laid in a narrow longitudinal saw

passing across the joint of logs. At the ends the propil has special slots in the form of triangular prisms.

|

|

|

Galvanized metal washers are put on the stud from both ends, and galvanized nuts are twisted on top of

them.

The nuts during the installation of the cut are twisted with force, resulting in a tight joint that will ensure

tight docking of the logs at the corners.

Unlike the use of clamps, there is a large area of contact between the washer and the wood,

accordingly, it is obtained by an order of magnitude less transmitted pressure (the pressure, as we

remember, is the force divided by the area)..

In addition, galvanized metal is practically free of corrosion and will not cause wood damage.

|

|

|

|

Fig.

1

|

|

Fig.

2

|

|

But it 's not all that simple, especially if we use a Canadian cup and a chip. Note the side view of Figure

1. It turns out to be a rather complex system. The stud must be deep enough into the wood because a

groove is made above the stud for the stud of the above log.

On the other hand, in the lower part of the log it is necessary to drink a cup, and in it still leave a stud

(sometimes called a Kurdish), and this stud is on both joined logs.

For stud laying it is necessary to make narrow and deep slot, its walls must be vertical and have strictly

specified dimensions. The manufacture of slots, in the form of triangular prisms, also requires

experience and snooping.

Apparently, the listed difficulties in working with the considered tie and increased requirements to the

skill of cutters stop most construction companies in applying this technique.

Nevertheless, the management of the company Rus Brevennaya puts the interests of the client above

temporary difficulties in training the personnel and widely applies the approach considered in the

construction of cuts for its customers.

|

| |

|

|

|

|

|

|

|

Fig.

3

|

|

Fig.

4

|

|

|

|

|

|

Fig.

5

|

|

Fig.

6

|

Figures 2.. 5 above show the practice of connecting logs with metal ties. As an interesting detail - Figure

4 shows the nut and washer recessed into the slot. And what the ties themselves represent, is shown in

the photo of Figure 6.

By the way, note that these photos show a round log with a stall. This is a calling card of our

company, but we will tell about it in more detail

in another section.

This information is the intellectual property of Rus Log.

When reprinting materials, the link to the company 's website is mandatory.

|