|

Talk about the loft or what Norwegian cup and chop are.

|

Before to tell you about the technological features of logging houses from a carriage, it probably makes

sense to tell the guests of our site what exactly the carriages are and where it came from.

Lafet, or semi-oval log (Figure 1), came to us from Scandinavian countries, especially Norway. The free-

loving Vikings, who lived on sea-wind-blown coasts, knew the push in warm wooden houses.

There is a misconception that houses from the lafet are colder than those from the round log, it is not.

The thickness of the walls, usually about 20 cm, very warm cups in cuts (by the way, veils and spikes in

cups, lead their history from the Norwegian castle) provide comfortable accommodation in the northern

latitudes.

|

|

Fig. 1

Fig. 1 |

|

We would like to add that Norwegian people historically paint their homes with special compositions

(traditionally dark colors) that ensure the preservation of wood from the impact of the environment.

After all, if you pay attention to Figure 1, the outer, hardest, layer of wood and softer wood are removed

in the stall and exposed to the atmosphere. Nevertheless, existing antiseptics will be able to safely

protect your walls, leaving your eyes with the entire texture of the tree.

The photo on the right, Figure 2 shows a view of the Viking dwelling. On the roof, under a layer of snow,

there is a grass cover, pleasantly green in summer. The lower photo (a view of the inner wall of the

house) shows cracks and breaks occurring on the flat parts of the lafet.

In general, a laft is a whole philosophy. We are not talking about Norwegian, who traditionally cover the

roofs with a layer of soil with planted grass (so-called earth roofs, note - very warm, but require special

waterproofing).

If you are interested about the cracks and breaks of the structure of wood on your walls (they are never

through and do not reduce the heat protection of the walls).

|

|

Fig. 2

Fig. 2 |

In the following two figures (Figures 3 and 4), you can see what the loft houses produced by Rus Log

look like. As you can see, the stall creates a visual lightness of the cut design. In the near future we will

update the collection of finished houses from the lafet in our gallery.

Fig. 3

Fig. 4

In addition to this there are several other advantages of walls made of loft, these are:

Increase in the effective area of the premises, since you have a flat wall, with a thickness of only 20 cm.

For a round log, the thickness of the wall will vary from 24.. 28 cm to 40.. 50 cm, depending on the

thickness of the material you ordered;

- Convenience of wiring, water and gas supply;

- The convenience of placing wall cabinets, for example, in the kitchen or in the bathroom;

- A very dense and warm cup in the overrun, especially when compared to a round log bowl with no veil

and thorn;

- Lower cost of a house made of loaf (when compared to an option involving the creation of veils under

the carpentry on round logs).

Disadvantages, as mentioned above, include:

- Removal of the strongest outer layer of wood;

- Presence of cracks and breaks of wood structure on side surfaces (on a circular log, with observance of

the correct cutting technology, there will be no visible breaks, but only a small web of cracks).

Now that you have already got an idea of the peculiarities of the houses made according to Norwegian

technology, it is time to tell in detail about the subtleties in the construction of walls made of loft.

We hope that you have already got acquainted with the technologies used by us for round logs:"curtaining of external

corners", undercut formation,

creation of unloading cuts hanging

of external corners, formation of undercut, creation of unloading props, etc.

Let us draw your attention to the differences concerning the lafet:

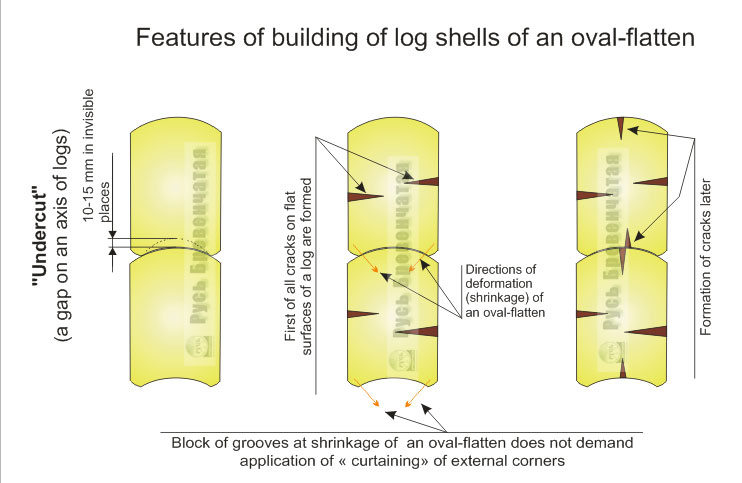

- On the basis of the characteristics of the behavior of the stub at shrinkage (Figure 5), which consists in

the primary formation of cracks on the side surfaces, the need to organize the hanging of external

angles is eliminated, as the gaps between the crowns are self-closing;

- Undercut in invisible places, on the contrary, is necessarily organized;

- Vertical discharge props in the upper parts of logs are also organized, however, they do not protect the

logs from cracking on the side surfaces, but only contribute to limiting their dimensions;

- The very technology of cutting into a Norwegian cup involves the use of veils and thorns in the overrun;

- No shading of openings for cash in door and window openings is required.

Fig. 5

|

|

|

In conclusion, consider the walls of the lafet closer.

Figure 6 shows the wall with the cut, pay attention to the second log from above - already on the

construction site cracks appeared along the log. Let it not scare you, it is a property of the lafet.

Figure 7 shows a large cut plan, please note the characteristic veils near the bowls, their purpose is

similar to those in Canadian chop cups.

Figure 8 shows the propyl in the window opening. A skull bar will be inserted into this propyl. For more

information on how to organize window and door openings, refer to the Opening Design section.".

|

|

Fig.

6

|

|

|

| |

|

|

|

|

|

|

|

Fig.

7

|

|

Fig.

8

|

P.S. P.S. If it is difficult for you to decide which type of log you choose: round or loft, we remind you that you

can combine them by making external walls from round, and internal walls from loft. About it in more

detail on the page "Kruglak lafet.;

The choice is yours, and the masters of the company Rus Log will help you to implement the house of

your dreams.

The

resulted information is the intellectual property of " Log

Russia".

At a reprint of materials, the reference to a company site is obligatory.

|